Introduction

This documentation describes and explains the Quantum Key Distribution system developped by VeriQloud. This documentation is still under construction.

Here is a datasheet of the system.

The source code can be found in the following repos

- kiwi_pcb (printed circuit boards)

- kiwi_fpga (fpga source code)

- kiwi_hw_control (hardware control software; deployment; monitoring)

The above repos together with this documentation make up the hardware of the system. That should get you up to the raw key.

Software on top of that, such as post processing, key management, QKD and non-QKD based applications can be made available on an individual basis. Please contact us directly.

PM-QKD

Prepare and Measure protocol (PM-QKD) includes a QKD transmitter party Alice and a QKD receiver party Bob. Alice prepares and sends quantum states to Bob through a quantum channel. Bob measures the quantum states. The result (after post-processing) is a common final key available to Alice and Bob.

Time bin encoding

Alice uses a continuous wave laser, cuts out two pulses with an amplitude modulator and applies a differential phase to the two pulses. One of four phases is choosen randomly in BB84 fashion. Bob also applies a random phase, interferes the pulses using an umbalanced Mach-Zehnder interferometer and measures them on single-photon detector. More details are provided in the optics section.

For decoy state QKD the amplitude of the double pulse is chosen randomly from a small set.

Our technological approach

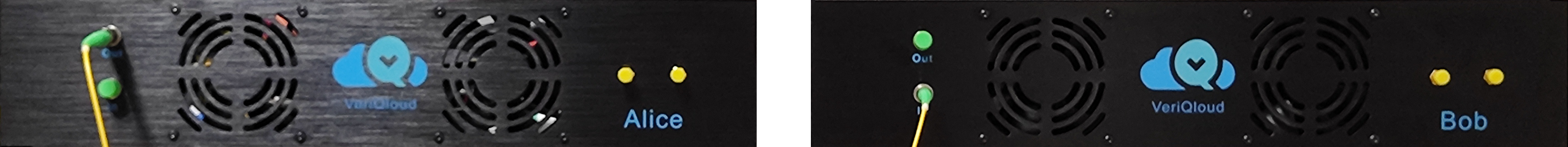

We adopt a modular design. The heart of the system is the VQ Card performing real time digital processing and analog control. This card together with the computer, some electronics and the optics is in a rack mountable enclosure. The classical network and clock distribution is external and must be provided for the system. The laser and detector are inside the encosure by default but can be made external for flexibility. This way, development teams can use their own laser or detector to best suit their project. The protocol we run on the system is standard BB84 with time-bin encoding. Other protocols can be implemented but might require modifications of the FPGA code and other components. The computer we use is a fairly powerful standard PC to leave room for custom postprocessing applications.

Our network philosophy is to separate the quantum and the classical network. The classical communication can happen over any ethernet connection. The reason behind this choice is that routing on the quantum network must be done with minimal optical losses. Coprapagation of the classical and the quantum signal on the same network inevitably increases the losses as well as the complexity. Nevertheless, shared networks are possible with proper filter designs. However, they depend strongly on the topologies and requirements of the operator. Such setups have not been tested with this system yet.

This is an overview of the logical levels. This architecture involves four layers (the physical hardware layer (PHY), the QKD Network Layer (here called Node), the key management service layer (KMS), the application layer (APP). Each layer can be modified independently of the other ones for more flexibility.

- The application layer consists of user devices and applications, which make key requests to the Key Management Service (KMS) layer. These devices and applications use these keys to encrypt data in a secure way.

- The KMS layer obtains keys from the quantum network layer and distributes the keys to their designated hosts in the application layer. The KMS layer must ensure the integrity and confidentiality of the keys.

- The Quantum Network Layer: executes all the post-processing steps on the keys produced from the physical layer to get final secure keys. It coordinates key routing between nodes and provides the keys directly to the KMS layer. The Veriqloud software doing these tasks is called Node.

- The physical hardware layer (PHY) consists of the quantum channel and physical QKD hardware devices. These devices are responsable for generating the keys. After a key is produced, it is passed to Node where it is processed as described above. The PHY layer and Node share data through PCIe.

We make the physical hardware layer as well as Node open source. The KMS and applications remain closed source.

Post processing

For the BB84 protocol without decoy states, there are three steps to process the raw key into the final key:

- Sifting: the basis choice for each detection event is compared between Alice and Bob and the non-matching events are discarded.

- Error correction: mismatched bits are corrected using parity checks (via a low-density parity check code).

- Privacy amplification: the key is compressed to compensate information leakage (via Toeplitz hashing). The number of bits leaked in error correction is exactly known. The number of bits leaked to Eve on the quantum channel can be estimated by \( h(\textrm{qber}) \), where \(h\) is the binary entropy function. The qber here is the measured qber plus a few standard deviations to account for finite size statistics.

Classical network and external clock

The system requires two external clocks, 10MHz and 1PPS (pulse per second). The stability between Alice and Bob should be around 100ps on a timescales of around 100us. This is to ensure Bob can measure the pulses with a 100ps precision. Absolute timing stability is not important.

The system also requires a standard ethernet network (e.g. 1Gbit/s) for low-level communication and post processing.

We use the White Rabbit Switch to do both over a single optical channel.

Optics

Alice

We use an external Laser: Thorlabs SFL1550P. Butterfly package, fully controlled by Laser Driver.

We have the following components on Alice's box:

- Amplitude Modulator iXblue MXER-LN-10-PD-P-P-FA-FA-30dB

- Phase Modulator iXblue MPZ-LN-10-P-P-FA-FA

- Filter from AMS OZ Optics custom band pass;

- passband: 1510nm - 1585nm

- transmission: 0.72dB @ 1550nm

- rejection: 61dB @ 850nm, 30dB specified elsewere

- Variable Attenuator: Voltage-controlled Attenuator on Dark Mode fs.com

- Manual Attenuator: Manual Attenuator Thorlabs VOA50

Bob

We have the following components on Bob's box:

- Filter from AMS OZ Optics custom band pass;

- passband: 1510nm - 1585nm

- transmission: 0.72dB @ 1550nm

- rejection: 61dB @ 850nm, 30dB specified elsewere

- Polarization modulator from AMS LUNA (General Photonics). After Polarization Modulator all fibers are polarization maintaining ones P3-1550PMY-1.

- In Line Fiber Polarizer from Thorlabs

- Phase Modulator iXblue MPZ-LN-10-P-P-FA-FA

- Interferometer. Fully passive with two Polarization maintaining beam splitters PN1550R5A2 (BS) + one Polarized Beam Splitter (PBS) + 2m Polarization maintaining fiber PMP-15-R-L-2-2SA-2SA + 1m Polarization maintaining fiber PMP-15-R-L-1-2SA-2FA. All ends for all BS and PBS used for the interferometer are with the narrow key of each connector aligned to the slow axis of the fiber. Only 2m Polarization maintaining fiber has the narrow key of one connector aligned to the fast axis of the fiber (the one connected to the input of PBS)

For detection, we use an external Avalanche Photo Diode OEM module by Aurea (standard grade) with datasheet.

Drivers and amplifiers

-

Laser driver: Koheron CTL300E

- Communication over serial from FPGA.

- 6V-33V power.

-

Amplifier for Amplitude Modulator: ZX60-4016E-S+, pdf datasheet.

- Power: 12V 400mA.

- Vamp 0V-0.9V to control the gain.

- 21dB gain, 8Vpp output max.

- SMA in/out.

-

Amplifer for Phase Modulator of Alice: ZHL-2X-S+, pdf datasheet.

- Power: 24V 600mA

- 20dB gain, 17.8Vpp max

- SMA in/out

-

Amplifer for Phase Modulator of Bob: ZHL-32A-S+, pdf datasheet.

- Power: 24V 600mA

- 25dB gain, 17.8Vpp max

- SMA in/out

-

Pulse generator: Highland Technologies J240

- Power: 12V

- 140ps FWHM pulse, 0V-0.75V pulse amplitude

- Adjustable trigger level

Electronics

As reminder, here is the logical overview of the system

The physical layer (PHY) is in charge of generating the raw keys, which are then passed to Node. The PHY layer includes:

- Physical hardware

- Device driver and Control API

Physical hardware

This is an overview of the physical hardware. There are 2 groups of components:

- Optics and their drivers: Laser, Laser Driver, Pulse Generator, Amplifiers, Single Photon Detector, other optical components. The detail of each components and physical connections are explained in Optics chapter

- Electronics: White Rabbit Switch (WRS), Power Supply system, digital to analog converters (DA) and other electronics components.

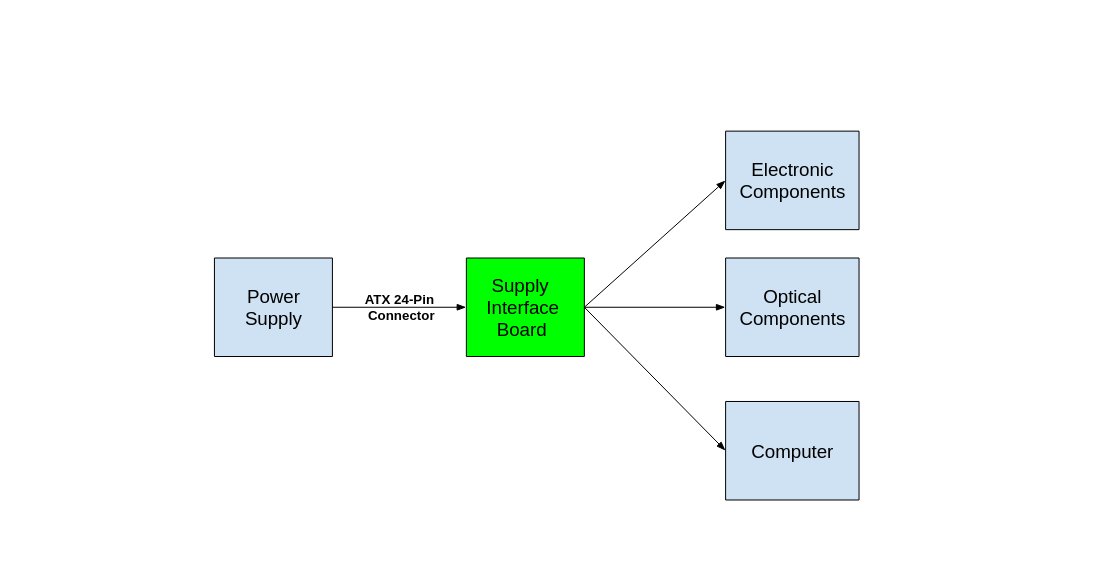

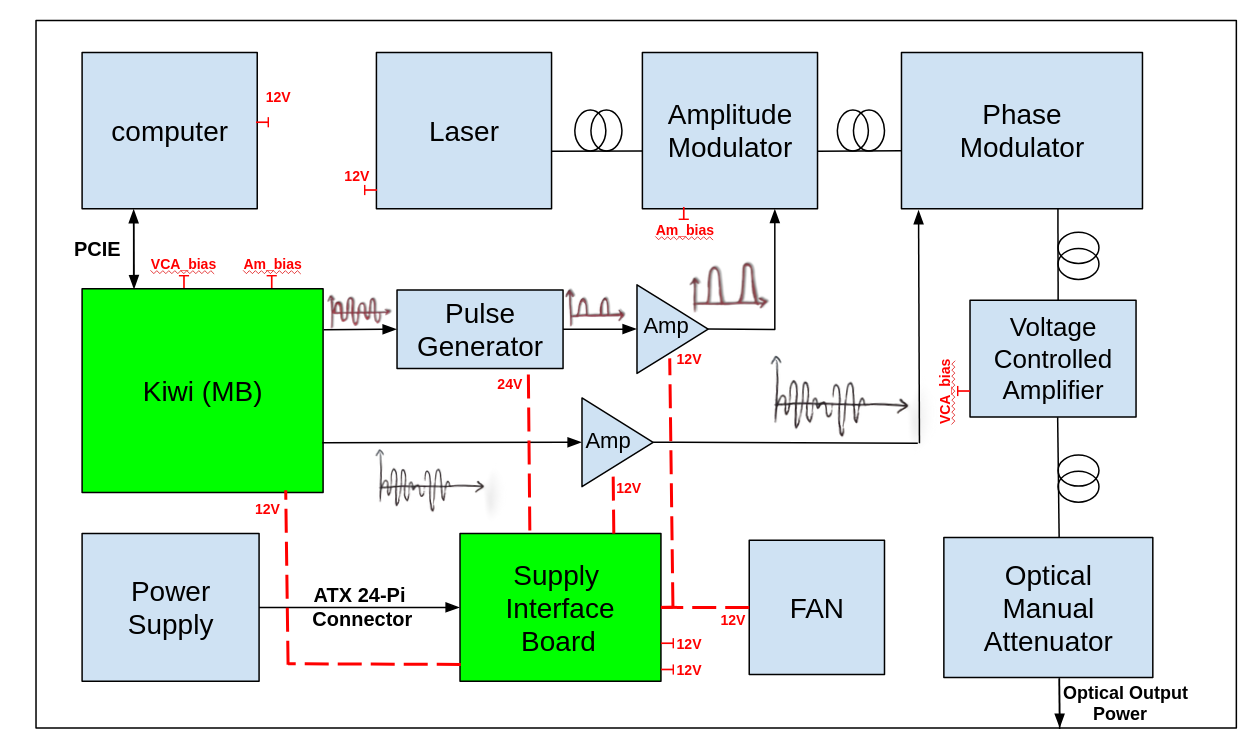

The picture below shows the system of electronics, electrical power supply and interface with Optics.

Some abbreviations: Pulse Generator (PG), Amplitude Modulator (AM), Single Photon Detector (SPD), true Randon Number Generator (tRNG), Personal Computer (PC), Time to Digital Converter (TDC), Digital to Analog Converter (DAC)

Device driver and Control API

To complete the PHY layer, it requires a software layer to control the physical hardware. It includes:

- Device driver: this is the low-level software handles PCIe communication (using XDMA) between PC and FPGA. It operates at OS kernel level and is written by AMD (Xilinx)

- Control API: this is the high-level software that runs at user level to configure and control the FPGA via the device driver. The user sends commands and data to FPGA from this API

Instructions to install the driver and source code of Control API is available in kiwi_hw_control github repos. Os level documentation is also provided in the User Guide section.

Sub-Chapters

- PCB board design: describes the Motherboard Bread70, Power Supply Distributors, ATX, Power Meters, and future PCB designs

- FPGA programming: describes logic design in FPGA and corresponding Control API

- WRS, Computer, tRNG: details of these components

Design PCB

In this section, we will describe the PCB design for the power interface and Kiwi MB, as well as the specific functionalities implemented on these boards, their role, and their integration into the overall system.

I. Supply Interface Board

The Supply Interface Board acts as an interface between the main power supply and the electronic, optical, and computer components, as shown in the figure below.

Spécifications:

Outputs:

- 6 × 12 V (total 24 A),

- 1 × 5 V/1 A,

- 1 × ±12 V (total 1.2 A/0.1 A),

- 1 × 24 V/0.6 A.

Main Power Supply:

- Powered by a PC ATX power supply connected via a 24-pin ATX connector.

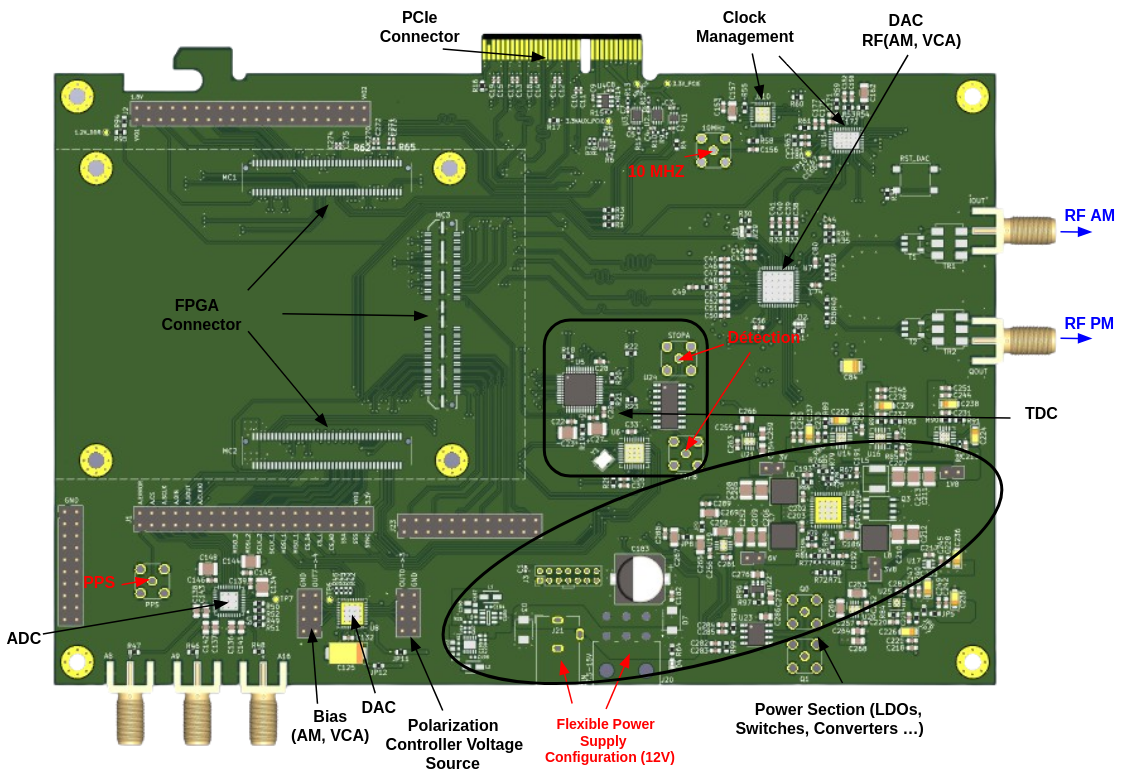

II. Kiwi_MB

The Kiwi Motherboard (Kiwi_MB) is designed for the management and processing of analog and digital signals. It features a slot for the XEM8310 FPGA from OpalKelly, a PCIe connector for interfacing with the computer, as well as a section dedicated to clock and power management. The board also includes DACs and ADCs with SMA inputs and outputs for signal processing.

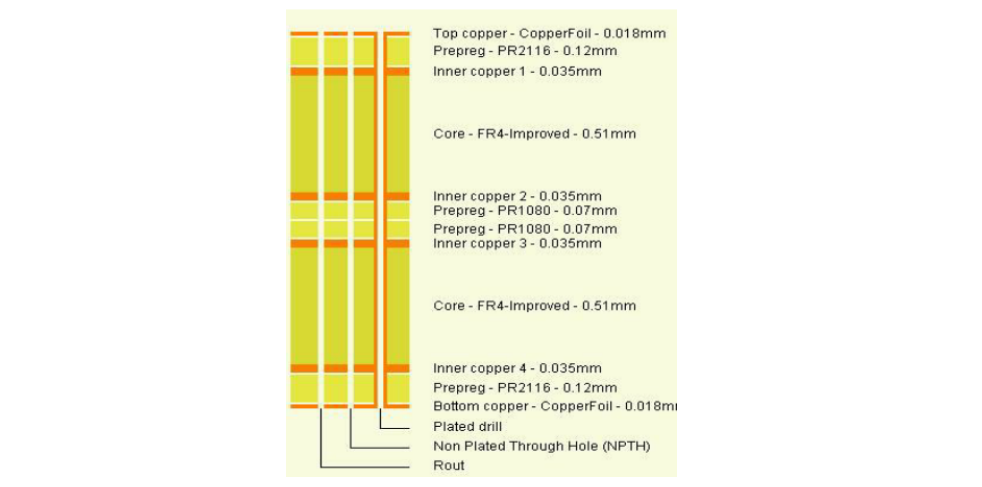

Materials and Stack-up

| Category | Détails |

|---|---|

| Dimensions | Width: 200.0 mm, Height: 138.4 mm |

| Number of layers | 6 (see the figure below) |

| Board thickness | 1.55 mm |

| Base material | IS400 (Tg: 145-150°C) |

| Copper | Outer layer: 18μm, Inner layer: 35μm |

| Minimum hole size | 0.45 mm |

| Trace design | All traces are designed to ensure optimal adaptation to signal frequencies and power, maintaining a characteristic impedance of 50 ohms. |

Functionalities Implemented on Kiwi_MB PCB:

Power Management:

The Kiwi Motherboard (Kiwi MB) is powered by a 12 V supply, which is then converted into multiple voltages through the following Power Management system:

- Five Buck Converters: Producing 1.8 V, 3.8 V, 3 V, 6 V, and 10.5 V.

- One Buck-Boost Converter: Generating an inverted -10.5 V.

- The system includes twelve jumpers: four standard connectors and eight 0 Ω resistors, which must be installed one at a time, verifying the voltages at each step.

- Finally, 8 Linear Regulators (LDO) provide additional voltages: 3.3 V (x2), 2.5 V, 3.8 V, 5 V, and 1.2 V (x3), ensuring stable power for the components.

Clock Management:

The clock management architecture aims to manage synchronization signals in order to improve the system's precision. A 10 MHz reference signal from the White Rabbit Switch (WRS) is sent to the CDCLVD2104, a clock signal buffer, which then passes it to the LTC6951 to generate the necessary clocks for the AD9152 fast DACs, as well as for the TDC and TTL Gate via the FPGA. The CDCLVD2104 also generates the 10 MHz SPI synchronization signal. Additionally, the PPS (Pulse Per Second) signal from the WRS is used as a reference signal for clock alignment, ensuring precise synchronization of the system's components.

DACs and ADCs:

Kiwi_MB contains two DACs and one ADC for signal conversion and generation:

- DAC81408RHAT: This DAC is used to generate polarization voltage signals (AM and VCA) on channels 6 and 7, as well as for the polarization controller on channels 0 to 3.

- AD9152 Fast DAC: A high-speed DAC used to generate the RF signals RF_AM and RF_PM, necessary for producing analog RF outputs sent to the amplitude and phase modulators.

- AD7175-8 ADC: An analog-to-digital converter with three inputs for converting analog RF signals into digital format for further processing.

- These components are managed by the FPGA to ensure efficient signal conversion and the generation of the necessary voltages for the different channels.

TDC:

The TDC system uses four components to convert the arrival times of qubits into digital data. The single-photon detector generates raw data, which is retrieved via an SMA connector and sent to the DS90C031B, an LVDS driver, and then transmitted to the AS6501. The AS6501, a Time-to-Digital Converter (TDC), measures the arrival times and converts them into digital data. The reference signal, generated by the ECX-32 crystal and the Si55319, synchronizes the entire system by producing a differential signal sent to the AS6501, ensuring precise time measurements.

Integration of the Kiwi_MB and Supply Interface Board in the Kiwi Box

Below is a diagram illustrating an example of the integration of the Kiwi_MB and the power interface board, as well as their interaction with the electronic and optical components in Alice's box.

FPGA module introduction

The FPGA integration module XEM8310-AU25P is a product of opalkelly, using AMD Artix UltraScale+ FPGA. All information about XEM8310 is available on Documentation portal of opalkelly. From website you can also download:

- FrontPanel to setting devices, loading bitstream, flash,...

- Vivado board file

- Pins list

This FPGA module will be plugged to the "Bread70" PCB to communicate with all ICs on board.

Vivado project

The RTL source code and Vivado block design is available on GitHub kiwi_fpga. Follow the instructions in README to rebuild Vivado project and block design from Tcl script. Then you have fully access to the project and can generate the bitstream for FPGA on your local machine.

The main blocks in project:

- XDMA

- Clock and reset

- Fastdac

- TDC

- DDR4

- TTL gate

- Decoy signal

- SPI

- ILA debug

Reading the detail of each block in sub-chapters

Prepare FPGA board

Configuration VIO voltage for XEM8310 is the first step to do after getting FPGA. Simply download the FrontPanel API from opalkelly website to your local machine, connect the USB-C and change these VIO settings:

- VIO1 = 1.8V

- VIO2 = 2.5V

- VIO3 = 3.3V

Restart the FPGA module and verify the VIOs. Then you can plug FPGA module to power verified Bread70.

Loading bitstream

There are 2 ways to load bitstream to FPGA

- USB and FrontPanel API: Install FrontPanel API and Configure Device with your bitstream

- JTAG: Simply Open Vivado Hardware manager, Open target and Program device

You can only have access to ILA debug windows in Vivado by JTAG. With this solution, you also can check the Calibration Process of DDR4. I tested severals FPGA modules with the same bitstream, some of them pass the Calibration Process smoothly, some don't.

Flashing bitstream

Using JTAG

Specification

There are 2 non-volatile memory to flash board XEM8310. Read Specification of the board

- System Flash

- FPGA Flash

We are going to choose FPGA Flash mode, using 32MiB QSPI non-volatile memory Opalkelly Flash Memory

Generate specific bitstream

Usually, you generate bitstream in vivado -> top.bit configuration file To be able to load .bit configuration to Flash Memory. Add these to .xdc constraint

set_property BITSTREAM.CONFIG.EXTMASTERCCLK_EN disable [current_design]

set_property CONFIG_MODE SPIx4 [current_design]

set_property BITSTREAM.CONFIG.SPI_BUSWIDTH 4 [current_design]

set_property BITSTREAM.CONFIG.SPI_FALL_EDGE YES [current_design]

set_property BITSTREAM.CONFIG.CONFIGRATE 85.0 [current_design]

Generate bitstream with these added constraints -> top.bit. This bit file only can be used by load it to FPGA Flash

Create the memory configuration .mcs file

In vivado: Tools -> Generate Memory Configuration File -> Choose...

- Format: MCS

- Memory Part: IS25WP256D-x1x2x4

- Filename:/PATH_TO/top.mcs

- Interface:SPIx4

- Load bitstream files: /PATH_TO/top.bit

- Start Add at 0, direction up

Click OK to generate top.mcs

Load the memory configuration file

In vivado:

- Open Hardware Manager

- Right click on Target -> configuration Memory Device

- choose the Memory part, top.mcs

- Choose: Erase, Program, Verify

- Program -> Wait it to finish

Power cycle

Turn off and turn on FPGA. The bitstream should be loaded after 2-3s. Ready to check

Using FrontPanel

Generate the specific bitstream as Using JTAG method

Download and install FrontPanel

run:

sudo ./install

build flashloader

cd Samples/FlashLoader/Cxx/

sudo make

Download the Samples for XEM8310

- Download from opakelly Files Download

- copy the flashloader.bit to ../Samples/Flashloader/Cxx/

Load bitstream

Create a bash script to flash your specific bitstream in /PATH_TO_BIT/

#!/bin/bash

pushd FrontPanel-Ubuntu22.04LTS-x64-5.3.6/Samples/FlashLoader/Cxx/ || exit 1

flashloader w /PATH_TO_BIT/Bob_top_wrapper.bit

popd

Power cycle the board and check

XDMA

XDMA block use "DMA for PCI Express (PCIe) Subsystem" IP supported by AMD. You can click the IP in block design to see the configuration parameters. For Kiwi device:

- Use 4 lanes at full speed 8GT/s

- Axilite 32 bits

- Axilite master space 32MB

- Axistream 128 bits, clock 250MHz

- Use full 4 axistream channels (H2C/C2H)

The picture below shows the actual number of channel and purpose of each channel

From Axil of XDMA, connect with AXI Interconnect IP to divide address space for sub-modules. Changing the size of address space depends on the number of registers need to be written through Axil to Axil of sub-modules. You can check the Axil address distribution in block design or in the table below:

| Offset | Range | Target RTL module/ IP |

|---|---|---|

| 0x0000_0000 | 0x0000_1000 4K | tdc/tdc_mngt/TDC_REG_MNGT_v1_0.v |

| 0x0000_1000 | 0x0000_1000 4K | ddr4/ddr_data_reg_mngt.v |

| 0x0001_0000 | 0x0000_1000 4K | fastdac/jesd204b_tx_wrapper.v |

| 0x0001_2000 | 0x0000_1000 4K | clk_rst/clk_rst_mngt.v |

| 0x0001_3000 | 0x0000_1000 4K | tdc/time_spi/axi_quad_spi |

| 0x0001_5000 | 0x0000_1000 4K | ttl_gate_apd.v |

| 0x0001_6000 | 0x0000_1000 4K | decoy.v |

| 0x0002_0000 | 0x0001_0000 8K | spi_dacs_ltc/axi_quad_spi |

| 0x0003_0000 | 0x0008_0000 64K | fastdac/jesd_transport.v |

Clock and reset management

Clock tree

This is an overview of the clock distribution for Kiwi device. There are 3 clock sources:

- Source 100 MHz for PCIe comes from mother board of PC

- Source 100 MHz for DDR4 comes from oscilator on XEM8310 modules

- Source 10 MHz and PPS comes from White Rabbit Switch(WRS)

WRS 10 MHz is reference for PLL LTC6951 to generate clock pairs (sysref 3.125 MHz and refclk 200 MHz) for Fast DAC AD9152 and FPGA. PLL LTC6951 requires a SYNC signal to align all outputs to input, I use WRS PPS and 10 MHz to generate this signal, then the outputs will be aligned to PPS.

reflck 200 MHz is is the source clock for all logics in fpga, PPS is reference for synchronization

Module RTL

Purpose of this module:

- Manage the input clocks

- Generate the resets for other RTL modules

- Generate SYNC signal for clockchip on board Bread70

Port descriptions

| Signals name | Interface | Dir | Init status | Description |

|---|---|---|---|---|

| fastdac_refclki_p/n | cr_ext_cr | I | 200MHz | input of jesd refclk from clockchip |

| fastdac_sysref_p/n | cr_ext_cr | I | 3.125MHz | input of jesd sysref from clockchip |

| fastdac_syncout_p/n | cr_ext_cr | I | - | input of jesd syncout from receiver |

| ext_clk10_p/n | cr_ext_cr | I | 10MHz | input of 10MHz from WRS |

| ext_clk100_p/n | cr_ext_cr | I | 100MHz | input of 100MHz from clockchip |

| axil signals | s_axil | IO | - | standard axilite interface for r/w registers |

| s_axil_aclk | Clock | I | 15MHz | clock for axil interface |

| sys_reset_n | Reset | I | - | system reset, active LOW |

| clk_ddr_axi_i | Clock | I | 300MHz | clock to generated from MMCM of DDR4 |

| rst_ddr_axi_i | Reset | I | - | reset synced to clk_ddr_axi_i |

| fastdac_gt_powergood_i | - | I | - | powergood indicator of jesd204B core |

| pps_i | - | I | - | PPS from WRS |

| lclk_i | Clock | I | - | lclk domain of tdc module |

| rstn_axil_o | Reset | O | - | Reset axil interface in others modules |

| rstn_ddr_axi_o | Reset | O | - | Reset AXI interface of DDR4 |

| fastdac_refclk_o | Clock | O | 200MHz | Refclk for QPLL in JESD204_PHY IP |

| fastdac_coreclk_o | Clock | O | 200MHz | Clock for logic in 200MHz domain |

| fastdac_corerst_o | Reset | O | - | Reset for fastdac core |

| fastdac_sysref_o | Clock | O | 3.125MHz | Sysref for jesd204b core |

| fastdac_syncout_o | - | O | - | syncout for jesd204b core |

| clk10_o | Clock | O | 10MHz | clk10 SE (single-ended) |

| clk100_o | Clock | O | 100MHz | clk100 SE |

| sync_ltc_o | Clock | O | 2ms HIGH | SYNC signal for clockchip output alignment |

| tdc_rst_o | Reset | O | - | Reset for tdc clock reset module |

| lrst_o | Reset | O | - | Reset for tdc module in lclk domain |

| ttl_rst | Reset | O | - | Reset for ttl_gate module |

| decoy_rst | Reset | O | - | Reset for decoy module |

| gc_rst_o | Reset | O | - | Reset for tdc module in clk200 domain |

| ddr_data_rstn_o | Reset | O | - | Reset for ddr_data module |

User parameters

| Parameter | Value | Description |

|---|---|---|

| C_S_Axil_Addr_Width | 10 | Address width of axil interface |

| C_S_Axil_Data_Width | 32 | Address width of axil interface |

Axilite registers:

- Base Address: 0x0001_2000

- Offset address slv_reg(n) : 4*n

slv_reg0 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:2 | - | - | - | Reserved 0 |

| 1 | clockchip_sync_o | clockchip_sync | Pull LOW to HIGH | Send trigger to generate SYNC signal for external clockchip |

| 0 | fpga_turnkey_fastdac_rst_o | fpga_turnkey_fastdac_rst | Pull HIGH to LOW | Reset fastdac core, active HIGH |

slv_reg1 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:2 | - | - | - | Reserved 0 |

| 1 | tdc_rst_o | tdc_rst | Pull HIGH to LOW | Reset tdc clock management, active HIGH |

| 0 | lrst_o | lrst_i | Pull HIGH to LOW | Reset tdc module in lclk domain, active HIGH |

slv_reg2 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | gc_rst_o | gc_rst | Pull HIGH to LOW | Reset tdc module in clk200 domain, active HIGH |

slv_reg3 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | ttl_rst_o | ttl_rst | Pull HIGH to LOW | Reset ttl module, active HIGH |

slv_reg4 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | ddr_data_rst | ddr_data_rst | Pull HIGH to LOW | Reset ddr_data module, active HIGH |

slv_reg5 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | decoy_rst_o | decoy_rst | Pull HIGH to LOW | Reset decoy module, active HIGH |

slv_reg6 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | ltc_sync_rst_o | ltc_sync_rst | Pull HIGH to LOW | Reset decoy module, active HIGH |

Generate SYNC signal for clockchip

After receiving sync trigger command from OS, FPGA detects rising edge of PPS and start counting to generate a 2ms pulse for clockchip (minimum is 1ms). Order of commands:

- Initialize clock chip : writing configuration registers

- Reset the sync counter

- Send the sync trigger

- FGPA should return the SYNC pulse for clock chip, the outputs of clock chip should be aligned to reference clock

- Each time there'a any change in configuration registers, new parameters is applied after SYNC

Note: This SYNC is different with SYNC on DDR

Fast DAC

We use fast DAC chip AD9152 from Analog Device, converts digital to analog signal. So FPGA will be Transmitter and AD9152 is Receiver. This IC includes 2 DACs:

- DAC0 : output IOUT

- DAC1 : output QOUT

Kiwi device has qu-bit rate 80MHz, we use time-bin encoded, so DAC0 in Alice generates double pulse at 80MHz, DAC1 also generates signal for PM at the same rate. We calculated the JESD204B parameters before designing the sytem, you can find the parameters in registers we set for the chip. We set:

- lane rate 10Gbits/s per lane

- 4 lanes

- jesd in mode 4

- subclass 1

- refclk 200MHz

- sysref clk 3.125MHz

Read JESD204 Survival Guide and AD9152 datasheet to understand protocol. Read chapter JESD204B Setup in AD9152 datasheet to calculate lane rate.

Receiver AD9152

- refclk and sysref comes from clock chip ltc9152

- registers setting in order by these functions in control software

Set_reg_powerup()

Set_reg_plls()

Set_reg_seq1()

Set_reg_seq2()

Transmitter FPGA

fastdac block is splited into 3 layers:

- jesd transport: module jesd_transport.v

- jesd: module jesd204b_tx_wrapper.v

- jesd phy: IP jesd204 phy

To synchronise the output with PPS, add an extra module to sync_tx_ready to PPS

Sync_tx_tready

This module will synchronize tx_tready to PPS to make sure the analog output of the Receiver will be synced

Port descriptions

| Signals name | Interface | Dir | Init status | Description |

|---|---|---|---|---|

| pps_i | - | I | - | PPS from WRS |

| tx_core_clk | Clock | I | 200MHz | clock for logic |

| tx_core_rst | Reset | I | - | reset for jesd tx core |

| tx_tready | I | - | signal from jesd, ready to send data | |

| tx_tready_o | O | - | tx_tready synced to PPS |

Jesd transport

Generate data to provide for Jesd. There are 2 DACs inside AD9152, so DAC0 in charge of signal for AM, DAC1 in charge of signal for PM.

- Maximum output power for each DAC is 600mV peak-to-peak into 50 Ohm load

- Sampling rate for each DAC: 800M sample/s, qubit rate = 80 MHz. So you have 10 samples for 1 double pulse period

Signal for AM

- qbit is encoded in 5 ns double pulse, pulse rate is 80MHz (12,5ns). Pulse Generator(PG) triggers the rising edge of the DAC0 signal to generate the pulses, so make sure distance between 2 rising edge is 5ns +- 200ps. You can play around with Pulse Generator threshold and DAC0 signal to find the best position for PG trigger

Signal for PM

- Amplitude of DAC1 signal defines the phase difference applied to 2 bins from 0 to 2\(\pi\). Depends on power of the PM amplifier, you can reach higher amplitude. Two peaks of PM signal for 1 qubit is symetrique.

- With BB84 protocol, the phase is random, there are 4 phase possibilities. Which means 1 double pulse requires 2 bits of rng, rng data rate = 80M* 2 = 160Mbits/s

- SwiftPro RNG USB output RNG data at roughly 200Mbits/s. So you have to read from fifo output 4bits at 40MHz -> 4bits rng selects the amplitude for DAC1 signal

- For the purpose of calibration, there is one option, rng can be put to dpram and read out 4bits at 40MHz. Knowing value of rng helps finding position of modulated qubit

- For visibility, apply sequence of 64 phases (from 0 to 2\(\pi\) or higher)

- Signal can be shifted 10 steps, 1,25ns each step

Port descriptions

| Signals name | Interface | Dir | Init status | Description |

|---|---|---|---|---|

| axil signals | s_axil | IO | - | standard axilite interface for r/w registers |

| s_axil_aclk | Clock | I | 15MHz | clock for axil interface |

| s_axil_aresetn | Reset | I | - | reset for axil interface, active LOW |

| s_axis_tdata[127:0] | s_axis | I | - | rng data from xdma0_h2c |

| s_axis_tvalid | s_axis | I | - | stream valid indicator |

| s_axis_tready | s_axis | O | - | raise high when ready to receive data |

| s_axis_clk | Clock | I | 250MHz | clock for axis interface |

| s_axis_tresetn | Reset | I | - | reset for axis interface, active LOW |

| tx_tdata[127:0] | tx | O | - | send data to jesd layer |

| tx_tready | tx | I | - | jesd indicator ready to receive data |

| tx_core_clk | Clock | I | 200MHz | clock domain for logic |

| tx_core_rst | Reset | I | - | reset for logic, active HIGH |

| tdata200_mod | - | I | - | data from tdc |

| gate_pos0/1/2/3 | - | I | - | gate_pos0/1/2/3 from tdc |

| q_gc_time_valid_mod16 | - | I | - | q_gc modulo 16 |

| rd_en_4 | - | O | - | enable signal at 40MHz |

| rd_en_16 | - | O | - | enable signal at 10MHz |

| rng_value[3:0] | - | O | - | rng data send to ddr to save |

| other ports | - | O | - | for debugging |

User parameters

| Parameter | Value | Description |

|---|---|---|

| C_S_Axil_Addr_Width | 16 | Address width of axil interface |

| C_S_Axil_Data_Width | 32 | Address width of axil interface |

Axil registers

From the Axil address distribution table, module target jesd_transport takes 64K from offset 0x0003_0000

| Offset | max address | Range | Target |

|---|---|---|---|

| 0x0003_0000 | 0x0003_1000 | 4096 | Regs for parameters |

| 0x0003_1000 | 0X0003_2000 | 4096 | Data for dpram_seqs |

| 0x0003_2000 | 0X0004_0000 | 57344 | Data for dpram_rng |

Tables of Registers for parameters, base is 0x0003_0000 Address of slv_reg(n) = 0x0003_0000 + 4 * n

slv_reg1 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:16 | fastdac_up_offset_o | fastdac_up_offset_o | - | up offset in feedback mode of Bob |

| 15:8 | - | - | - | Reserved 0 |

| 7:4 | fastdac_zero_pos_o | fastdac_zero_pos_i | max 15 | Define position to insert the zero on PM signal |

| 3:0 | fastdac_amp_dac1_shift_o | shift_i | max 10 | shift step for PM signal |

slv_reg2 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:16 | fastdac_amp_dac1_o | fastdac_amp_dac1_i | - | amplitude0 for PM signal |

| 15:0 | fastdac_amp_dac1_o | fastdac_amp_dac1_i | - | amplitude1 for PM signal |

slv_reg3 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | dac1_reg_en_o | reg_en_o | Pull LOW to HIGH | Enable to update registers |

slv_reg4 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:16 | - | - | - | Reserved 0 |

| 15:8 | fastdac_dpram_max _addr_seq_dac1_o | fastdac_dpram_max _addr_seq_dac1_i | - | dpram_seq max read add |

| 7:0 | fastdac_dpram_max _addr_seq_dac0_o | fastdac_dpram_max _addr_seq_dac0_i | - | dpram_seq max read add |

slv_reg5 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:5 | - | - | - | Reserved 0 |

| 4 | fastdac_dac0_mode_o | fastdac_dac0_mode_i | 1:fpga hardcoded sequence 0:from dpram | Choose which sequence for AM signal |

| 3 | fastdac_zero_mode_o | fastdac_zero_mode_i | 1:enable 0:disable | Enable insert zeros to PM signal |

| 2 | fastdac_fb_mode_o | fastdac_fb_mode_i | 1:enable 0:disable | Enable feedback mode on Bob |

| 1 | fastdac_dac1_mode_o | fastdac_dac1_mode_i | 1:fpga hardcoded sequence 0:from dpram | Choose which sequence for PM signal |

| 0 | fastdac_rng_mode_o | fastdac_rng_mode_i | 1:tRNG 0:dpram_rng | Choose which source of RNG |

slv_reg6 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:16 | fastdac_amp_dac2_o | fastdac_amp_dac2_i | - | amplitude2 for PM signal |

| 15:0 | fastdac_amp_dac2_o | fastdac_amp_dac2_i | - | amplitude3 for PM signal |

slv_reg7 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:15 | - | - | - | Reserved 0 |

| 14:0 | fastdac_dpram_max _addr_rng_dac1_o | fastdac_dpram_max _addr_rng_dac1_i | - | dpram_rng max read address |

Programming note

dpram_seqs: address range is 4096, maximum you can write 1024 words to each dpram

dpram_rng: address range is 57344, maximum you can write 14336 words to dpram_rng. For calibration procedure over:

- 100km optical fiber (0.5ms), you need a sequence of 20000 dpram_rng [3:0], means 2500 axil words

- 10km optical fiber, you need 2000 dpram_rng[3:0], means 250 axil words

fifos_rng: SwiftRro RNG output data rate around 200Mb/s, we read fifo in fpga at 160Mb/s.

There are several MUXs, simply choosing different modes for calibration purpose. When running the protocol, turn on all modes to 1

You have these 3 functions in software control to send data and write registers in jesd transport layer

Jesd

Our developper replaces AMD JESD204 IP by jesd204b_tx_wrapper.v so you don't need to pay AMD for JESD204 IP.However, this module supports only jesd204b protocol in mode 4 and mode 10. This function in software control sets all registers for jesd204b_tx_wrapper.v

Read Jesd204b overview written by our developper

Jesd phy

Physical layer, where the stream of data from jesd is mapped to 4 physical GT lanes. This IP is provided by AMD.

Process to run scripts

python main.py party_name --sequence arg0

python main.py party_name --shift arg0 arg1 arg2 arg3 arg4 arg5

python main.py party_name --fda_init

--sequence includes:

- write samples for DACs to dpram0 and dpram1 from file, arg0: choose double pulse, single pulse or 0 to generate on DAC0, fix sequence 64 angles on DAC1

- write rng sequence to rng_dpram from file

- write the max_address value to read out from dpram0, dpram1, rng_dpram

--shift:

- arg0: mode

Remind you setting mode in slave_reg5

| Slave_reg | Reg name | Description |

|---|---|---|

| slv_reg5[0] | fastdac_rng_mode_o | rng_mode |

| slv_reg5[1] | fastdac_dac1_mode_o | dac1_mode |

| slv_reg5[2] | fastdac_fb_mode_o | fb_mode |

| slv_reg5[3] | fastdac_zero_mode_o | zero_mode |

Depends on which calibration procedure, change the mode as your requirements

| rng_mode | description | usecase |

|---|---|---|

| 0 | fix sequence for dac1 to dpram | phase is sequence of 64 angles in linear amplitude |

| 2 | random amplitude, fake rng | find shift delay |

| 6 | random amplitude, true rng data, feedback on | find optical delay |

| 15 | random amplitude, true rng data, feedback on, insert zero | running qkd |

- arg1 to arg4: amplitude of the phase signal [from -1 to 1]

- arg5: shift value from 0 to 10

--fda_init:

-

Write configuration for jesd module

-

Reset jesd module

-

Set all registers for receiver ad9152

-

Read back some registers of receiver for monitoring

0x084 & 0x281: dac pll and serdes pll locked status0x302: dyn_link_latency, should be 0. Otherwise, run again the fda_init

0x470 to 0x473: all should be 0x0f, indicates all layers of jesd204b protocol is established

TDC

We use AS6501 TDC(Time to Digital Converter) chip to convert arriving time of q-bit to digital data. All modules and IP manage in/out signals from TDC are grouped under block tdc:

clk_rst_buffer

tdc_olvds.v: buffer for differential output signals, clocks

| Signals name | Interface | Dir | Init status | Description |

|---|---|---|---|---|

| tdc_lclki | Clock | I | - | source lclk for TDC chip |

| tdc_refclk | Clock | I | - | source refclk for TDC chip |

| tdc_rstidx | Reset | I | - | source rstidx for TDC chip |

| tdc_lclki_n/p | tdc_ext_clkrst | O | - | lclk differential pair output |

| tdc_refclk_n/p | tdc_ext_clkrst | O | - | refclk differential pair output |

| tdc_rstidx_n/p | tdc_ext_clkrst | O | - | rsridx differential pair output |

tdc_ilvds.v: buffer for differential input signals,clocks

| Signals name | Interface | Dir | Init status | Description |

|---|---|---|---|---|

| lclk_n/p | tdc_ext_in | I | - | lclk pair received from TDC chip |

| frameA_n/p | tdc_ext_in | I | - | frameA pair received from TDC chip |

| frameB_n/p | tdc_ext_in | I | - | frameB pair received from TDC chip |

| sdiA_n/p | tdc_ext_in | I | - | sdiA pair received from TDC chip |

| sdiB_n/p | tdc_ext_in | I | - | sdiB pair received from TDC chip |

| O_lclk | - | O | - | lclk in single-ended |

| O_frameA | - | O | - | frameA in single-ended |

| O_frameB | - | O | - | frameB in single-ended |

| O_sdiA | - | O | - | sdiA in single-ended |

| O_sdiB | - | O | - | sdiB in single-ended |

tdc_clk_rst_mngt.v : generate refclk 5MHz, rstindex for TDC; generate simulated STOPA signal for TDC

| Signals name | Interface | Dir | Init status | Description |

|---|---|---|---|---|

| clk200_i | Clock | I | - | clock source 200MHz |

| tdc_rst | Reset | I | - | reset active HIGH |

| pps_i | - | I | - | pps input from WRS |

| stopa_sim_limit[31:0] | - | I | - | registers to set division limit for stopa_sim |

| stopa_sim_enable_i | - | I | - | pull to high to update registers |

| tdc_refclk_o | - | O | - | generated refclk for TDC |

| tdc_rstidx_o | - | O | - | generated reset index for TDC |

| pps_trigger | - | O | - | trigger PPS event |

| stopa_sim | - | O | - | simulated STOPA of TDC |

- User parameters of tdc_clk_rst_mngt

| User Parameter name | Value | Description |

|---|---|---|

| N_COUNTER_APD | 800 | STOPA rate = 200M/(N_COUNTER_APD*divide_stopa) |

| N_TDC_REFCLK | 8 | Every 8 periods of refclk, generate a rstidx |

| TDC_DIV_HALF | 20 | refclk (MHz) = 200 (MHz) / (TDC_DIV_HALF*2) |

time_spi

Quad AXI spi: IP of AMD, manage to transfer data from AXI bus to spi bus. All information of IP is provided by Xilinx

spi_inout_mngt.v: mananage inout pins from quad AXI spi to physical spi pins

| Signals name | Interface | Dir | Init status | Description |

|---|---|---|---|---|

| mosi_io | com_ext_spi | IO | - | SPI MOSI |

| miso_io | com_ext_spi | IO | - | SPI MISO |

| ss_io[1:0] | com_ext_spi | O | - | SPI SS (2 bits for TDC and JITCLEAN) |

| sck_io | com_ext_spi | O | - | SPI SCLK |

| in0_i | - | I | - | connect io0_o of Quad AXI spi |

| in0t_i | - | I | - | connect io0_t of Quad AXI spi |

| out0_o | - | O | - | connect io0_i of Quad AXI spi |

| in1_i | - | I | - | connect io1_o of Quad AXI spi |

| in1t_i | - | I | - | connect io1_t of Quad AXI spi |

| out1_o | - | O | - | connect io1_i of Quad AXI spi |

| sck_i | - | I | - | connect sck_o of Quad AXI spi |

| sckt_i | - | I | - | connect sck_t of Quad AXI spi |

| sck_o | - | O | - | connect sck_i of Quad AXI spi |

| ss_i[1:0] | - | I | - | connect ss_o of Quad AXI spi |

| sst_i | - | I | - | connect ss_t of Quad AXI spi |

| ss_o[1:0] | - | O | - | connect ss_i of Quad AXI spi |

| rst_jic | - | O | HIGH | reset jitter cleaner |

system_ila_tdc

ILA debug core, probes signals under tdc blocks

tdc_mngt

tdc_core.v:

Manages digital data from TDC, output tdc time/global counter/click result depends on axil commands.

| Signals name | Interface | Dir | Init status | Description |

|---|---|---|---|---|

| m_axis signals | m_axis | IO | - | match with s_axis interface of fifo_gc_tdc_rtl.v |

| sr signals | sr | IO | - | match with mr interface |

| lclk_i | Clock | I | 200MHz | lclk |

| clk200_i | Clock | I | 200MHz | clk200 |

| m_axis_clk | Clock | I | 200MHz | clock for m_axsi interface |

| lrst_i | Reset | I | Active HIGH | reset in domain lclk |

| gc_rst | Reset | I | Active HIGH | reset in domain clk200 |

| fifo_calib_rst | Reset | O | Active LOW | reset for the s_axis interface of fifo_gc |

| linterrupt_i | - | I | - | interrupt signal from TDC |

| frame_i | - | I | - | frame signal from TDC |

| sdi_i | - | I | - | sdi signal from TDC |

| pps_i | - | I | - | PPS signal from WRS |

| rd_en_4 | - | I | - | enable signal at 40MHz |

| tvalid200 | - | O | - | indicates gc is valid in clk200 domain |

| tdata200 | - | O | - | time data value in clk200 domain |

| gc_time_valid[47:0] | - | O | - | gc value at the moment time data is valid |

| q_gc_time_valid_mod16[3:0] | - | O | - | gc value modulo 16 in 80MHz |

| tdata200_mod[15:0] | - | O | - | tdata200%625 |

| gate_pos0[31:0] | - | O | - | pos0 of soft_gate0 |

| gate_pos1[31:0] | - | O | - | pos1 of soft_gate0 |

| gate_pos2[31:0] | - | O | - | pos0 of soft_gate1 |

| gate_pos3[31:0] | - | O | - | pos1 of soft_gate1 |

| others | - | O | - | other signals is for debug |

tdc_reg_mngt.v:

Manages axilite registers.

User parameters: |Parameter |Value |Description |--------------------|------|------------ |C_S_Axil_Addr_Width |12 |Address width of axil interface |C_S_Axil_Data_Width |32 |Address width of axil interface

Port descriptions

| Signals name | Interface | Dir | Init status | Description |

|---|---|---|---|---|

| standard axil signals | s_axil | IO | - | s_axil interface for w/r registers |

| mr signals | mr | IO | - | registers of modules AS6501_IF.v (details in Axil registers) |

| stopa_sim_limit[31:0] | - | O | - | registers tdc_clk_rst_mngt.v (details in Axil registers) |

| stopa_sim_enable_o | - | O | - | registers tdc_clk_rst_mngt.v (details in Axil registers) |

| s_axil_aclk | Clock | I | 15MHz | clock for axil interface |

| s_axil_aresetn | Reset | I | Active LOW | reset for axil interface |

fifo_gc_tdc_rtl.v:

Instantiates fifo_gc_tdc, this fifo is axistream fifo. Instantiate axistream fifo in an RTL module allows to modify FREQ_HZ parameter of axistream interface when rebuild the block design.

| Signals name | Interface | Dir | Init status | Description |

|---|---|---|---|---|

| s_axis_tdata [127:0] | s_axis | I | - | axis stream data gc in |

| s_axis_tuser [3:0] | s_axis | I | - | axis stream tuser |

| s_axis_tvalid | s_axis | I | - | axis stream valid |

| s_axis_tready | s_axis | O | - | axis stream ready |

| m_axis_tdata [127:0] | m_axis | O | - | axis stream data gc out |

| m_axis_tuser [3:0] | m_axis | O | - | axis stream tuser |

| m_axis_tvalid | m_axis | O | - | axis stream valid |

| m_axis_tready | m_axis | I | - | axis stream ready |

| m_aclk | Clock | I | 250MHz | clock for m_axis interface |

| s_aclk | Clock | I | 200MHz | clock for s_axis interface |

| s_aresetn | Reset | I | - | reset for s_axis interface, active low |

Axil registers

- Base address: 0x0000_0000

- Offset address slv_reg(n) : 4*n

slv_reg0 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | tdc_enable | mr_enable | pull LOW to HIGH | Enable signal to receive sdi and frame from TDC |

slv_reg1 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:16 | - | - | - | Reserved 0 |

| 15:14 | tdc_index_stop _bitwise_o | mr_index_stop _bitwise_i | - | Reserved 0 |

| 13:8 | tdc_index_stop _bitwise_o | mr_index_stop _bitwise_i | default:14 | Define stop bitwise (match with TDC) |

| 7:6 | tdc_index_stop _bitwise_o | mr_index_stop _bitwise_i | - | Reserved 0 |

| 5:0 | tdc_index_stop _bitwise_o | mr_index_stop _bitwise_i | default:4 | Define index bitwise (match with TDC) |

slv_reg2 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | start_gc_o | mr_start_gc_i | pull LOW to HIGH | Enter START state of tdc |

slv_reg3 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:16 | stopa_sim_limit | stopa_sim_limit | max 512 | limit high: end of duty cycle |

| 15:8 | stopa_sim_limit | stopa_sim_limit | max 256 | limit_low : begin of duty cycle |

| 7:0 | stopa_sim_limit | stopa_sim_limit | max 256 | divide_stopa |

It depends on frequency of STOPA(in tdc_clk_rst_mngt.v) to set limit high and limit low for duty cycle. The limit value is in unit of clk200 period

slv_reg4 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:24 | gate0_o | mr_gate0_i | max 256 | define soft gate0 width |

| 23:0 | gate0_o | mr_gate0_i | max 625 | define soft gate0 start postion |

- Qubit rate is 80MHz(12.5ns)

- TDC resolution is 20ps

- Gate position should be in range 0..625

slv_reg5 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:24 | gate1_o | mr_gate1_i | max 256 | define soft gate1 width |

| 23:0 | gate1_o | mr_gate1_i | max 625 | define soft gate1 start postion |

slv_reg6 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:16 | - | - | - | Reserved 0 |

| 15:0 | shift_tdc_time_o | mr_shift_tdc_time_i | - | Define small shift for tdc time |

slv_reg7 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:16 | - | - | - | Reserved 0 |

| 15:0 | shift_gc_back_o | mr_shift_gc_back_i | - | Define small offset for gc |

slv_reg8 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:3 | - | - | - | Reserved 0 |

| 2:0 | tdc_command_o | mr_command_i | - | Define with mode (continuous or gated) to output gc |

slv_reg9 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:3 | - | - | - | Reserved 0 |

| 2 | stopa_sim_enable_o | stopa_sim_enable | Pull LOW to HIGH | Enable register update for stopa_sim |

| 1 | tdc_reg_enable200_o | mr_reg_enable200_i | Pull LOW to HIGH | Update registers in clk200 domain |

| 0 | tdc_reg_enable_o | mr_reg_enable_tdc_i | Pull LOW to HIGH | Update registers in lclk domain |

slv_reg10 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | tdc_command_enable_o | mr_command_enable | pull LOW to HIGH | Start filling gc to fifo |

slv_reg14 - R Access - Monitoring

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:0 | click1_count_i | mr_click1_count_o | - | monitoring click in soft_gate1 |

slv_reg15 - R Access - Monitoring

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:0 | click0_count_i | mr_click0_count_o | - | monitoring click in soft_gate0 |

slv_reg16 - R Access - Monitoring

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:0 | total_count_i | mr_total_count_o | - | monitoring total click in gated APD |

Data flow

Picture below shows an overview how data flows through modules and xdma channels. Responses to commands are written in modules tdc_core.v

Software control functions

Setting registers used in state machine under clk200

Initialize tdc module, global counter in tdc module is local, it means it's available in Bob only for calibration purpose. There are 2 state machines in tdc module:

- state machine under lclk_i: Config_Tdc() sets registers and enable this state machine, output digital data in FPGA

- state machine under clk200: Reset_gc() and Start_gc() send command to reset and start global counter

Get detection result, function Get_Stream() includes reset fifo_gc_tdc and read data from xdma0_c2h_*.

DDR4

Purpose of DDR4: when you get the click event on detection, you need to find the angle applied to that qubit (basis information). DDR4 is used to store the angle so that after getting click event, base on value of global counter, you can find the angle. One other reason is that we have constraints over 100km distance between Alice and Bob, the delay on classical channel, so DDR4 is large enough to satisfy these constraints. Below is the overview pictures of modules and IPs in FPGA manage the data flow in DDR4:

- IP DDR4: MIG IP supported by AMD. The core allow you interface directly with the physical Memory. To configure the MIG, follow instructions on opalkelly DDR4 Memory

- axi_virtual_controller_wrapper.v : use AXI Virtual FIFO Controller core from AMD to access DRAM memory as multiple FIFO blocks

- axi_clock_converter_rlt.v use AXI Clock Converter core from AMD as interconnect, change clock domain, because AXI interface on MIG uses 300MHz clock domain

- system_ila_ddr: monitoring AXI, AXIS interface and debug signals

- ddr_data_reg_mngt.v: manages axil registers for commands, settings, status monitoring

- ddr_data.v: manages data flow in/out axi_virtual_controller_wrapper, in/out xdma axistream fifos

- mon_ddr_fifos.v: manages registers to monitor status of AXI Virtual FIFO Controller and axistream fifos

- fifos_out.v: instantiate axistream output fifos. Instantiate in an RTL module allows Vivado changes FREQ_HZ parameter after rebuild block design from Tcl script

Port descriptions

axi_clock_converter_rtl.v

This module instantiates AXI Clock Converter IP of Xilinx. Post description is in Xilinx datasheet.

axi_virtual_controller_wrapper.v

This module instantiates AXI virtual Fifo Controller IP of Xilinx. Post description is in Xilinx datasheet.There are 3 optional ports for monitoring.

| Signals name | Interface | Dir | Init status | Description |

|---|---|---|---|---|

| counter_read[47:0] | - | O | - | number of read out of DDR AXI |

| counter_write[47:0] | - | O | - | number of write in of DDR AXI |

| delta_count[47:0] | - | O | - | number of write - number of read |

ddr4

This is IP of Xilinx. All information is in Xilinx datasheet

ddr4_data.v

| Signals name | Interface | Dir | Init status | Description |

|---|---|---|---|---|

| sr signals | sr | IO | - | match with mr interface of registers |

| s_axis_tdata[255:0] | s_axis | I | - | stream of angles reading from AXI Virtual FIFO |

| s_axis_tvalid | s_axis | I | - | valid indicator of angles reading from AXI Virtual FIFO |

| s_axis_tready | s_axis | O | - | raise tready high when want to read angles from DDR |

| s_axis_clk | Clock | I | 200MHz | Reading stream of angles in clk200 domain (reset of interface is ddr_data_rstn) |

| s_axis_tdata_gc[63:0] | s_axis_gc | I | - | stream of gc reading from xdma_h2c to write to gc_in fifo |

| s_axis_tvalid_gc | s_axis_gc | I | - | valid indicator of gc |

| s_axis_tready_gc | s_axis_gc | O | - | raise tready high when want to receive gc from xdma |

| s_axis_gc_clk | Clock | I | 250MHz | Reading stream of gc in clk250 domain |

| s_gc_aresetn | Reset | I | - | Reset of xdma |

| fifo_gc_full | - | O | - | full flag of gc_in fifo |

| fifo_gc_empty | - | O | - | empty flag of gc_in fifo |

| clk200_i | Clock | I | 200MHz | clk200 |

| pps_i | - | I | - | PPS from WRS for Alice capturing |

| ddr_data_rstn | Reset | I | - | reset in domain clk200, active LOW |

| rd_en_4 | - | I | - | 40MHz enable signal |

| rng_data[3:0] | - | I | - | random PM angle to write to DDR4 |

| rng_a_data[1:0] | - | I | - | ramdom 2nd AM angle to write to DDR4 |

| tvalid200 | - | I | - | TDC time valid |

| tdata200[31:0] | - | I | - | TDC time value of click |

| tdata200_mod[15:0] | - | I | - | TDC time value of click modulo 625 |

| gate_pos0/1/2/3[31:0] | - | I | - | softgate position to filter clicks |

| m_axis_tdata[255:0] | m_axis | O | - | stream of angles transmit to AXI Virtual FIFO |

| m_axis_tvalid | m_axis | O | - | valid indicator of written angles from logic |

| m_axis_tready | m_axis | I | - | Virtual FIFO raise high when it's ready to receive data |

| m_axis_clk | Clock | I | 200MHz | Writing to Virtual FIFO under clk200 domain (reset of interface is ddr_data_rstn) |

| m_axis_tdata_gc[63:0] | m_axis_gc | O | - | stream of gc+result write to gc_out AXIStream Fifo |

| m_axis_tvalid_gc | m_axis_gc | O | - | valid indicator of gc+result |

| m_axis_tready_gc | m_axis_gc | I | - | Fifo raise high to receive data |

| m_axis_gc_clk | Clock | I | 200MHz | Write domain is 200MHz |

| fifo_gc_rst | Reset | O | - | Reset for gc_out fifo, active HIGH |

| m_axis_tdata_alpha[127:0] | m_axis_alpha | O | - | stream of PM + 2nd AM angles write to alpha_out AXIStream Fifo |

| m_axis_tvalid_alpha | m_axis_alpha | O | - | valid indicator of angles |

| m_axis_tready_alpha | m_axis_alpha | I | - | Fifo raise high to receive data |

| m_axis_alpha_clk | Clock | I | 200MHz | Write domain is 200MHz |

| fifo_alpha_rst | Reset | O | - | Reset for alpha_out fifo, active HIGH |

| others ports | - | O | - | for debugging on ILA or external ports |

ddr_data_reg_mngt.v

| Signals name | Interface | Dir | Init status | Description |

|---|---|---|---|---|

| axil signals | s_axil | IO | - | standard axilite interface for r/w registers |

| s_axil_aclk | Clock | I | 15MHz | clock for axil interface |

| s_axil_aresetn | Reset | I | - | reset for axil interface, active LOW |

| pps_i | - | I | - | PPS from WRS for Alice capturing |

| ddr_fifos_status_i[8:0] | - | I | - | status of Virtual FIFO |

| status_200_valid_i | - | I | - | valid indicator of VFIFO status |

| fifos_status_i[2:0] | - | I | - | status of fifos in clk250 domain |

| status_250_valid_i | - | I | - | valid indicator of status in clk250 |

| mr signals | mr | O | - | interface of registers(details in axil registers) |

mon_ddr_fifos.v

| Signals name | Interface | Dir | Init status | Description |

|---|---|---|---|---|

| clk200_i | Clock | I | 200MHz | clk200 |

| ddr_data_rstn | Reset | I | - | reset in domain clk200, active LOW |

| clk250_i | Clock | I | 250MHz | clk250 |

| aresetn | Reset | I | - | reset in domain clk250, active LOW |

| vfifo_idle[1:0] | - | I | bit 0:channel 1 bit 1:channel 2 | idle flags for 2 channels of Virtual FIFO |

| vfifo_full[1:0] | I | bit 0:channel 1 bit 1:channel 2 | full flags for 2 channels of Virtual FIFO | |

| vfifo_empty[1:0] | - | I | bit 0:channel 1 bit 1:channel 2 | empty flags for 2 channels of Virtual FIFO |

| gc_out_fifo_full | - | I | - | full flag of gc_out fifo |

| gc_out_fifo_empty | - | I | - | empty flag of gc_out fifo |

| gc_in_fifo_full | - | I | - | full flag of gc_in fifo |

| gc_in_fifo_empty | - | I | - | empty flag of gc_in fifo |

| alpha_out_fifo_full | - | I | - | full flag of alpha_out fifo |

| alpha_out_fifo_empty | - | I | - | empty flag of alpha_out fifo |

| status_200_o[8:0] | - | O | - | status of flags in clk200 dmain |

| status_200_valid_o | - | O | - | indicator valid of status_200 |

| status_250_o[2:0] | - | O | - | status of flags in clk250 dmain |

| status_250_valid_o | - | O | - | indicator valid of status_250 |

fifos_out.v

This module instantiates 2 fifos: gc_out fifo and alpha fifo in AXIStream mode of FIFO Generator. Description of FIFO Generator is providded by Xilinx

Axil registers

- dq : double qubit, 40MHz

- LSB : Least Significant Bit

- MSB : Most Significant Bit

- Base address: 0x0000_1000

- Offset address slv_reg(n) : 4*n

slv_reg0 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | start_write_ddr_o | mr_start_write_ddr_i | Pull LOW to HIGH | Trigger to start write to ddr |

slv_reg1 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | command_enable_o | mr_command_enable_i | Pull LOW to HIGH | Trigger to get current gc |

slv_reg2 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:4 | - | - | - | Reserved 0 |

| 3 | command_gc_o | mr_command_gc_i | - | Unused |

| 2:0 | command_o | mr_command_i | 3:read_angle 4:reset alpha fifo | set command to read_angle mode or reset alpha_out fifo |

slv_reg3 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | reg_enable_o | mr_reg_enable_i | Pull LOW to HIGH | Enable register update |

slv_reg4 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:0 | dq_gc_start_lsb_o | mr_dq_gc_start_lsb_i | - | LSB of dq_gc, set to start save angles to alpha fifo |

slv_reg5 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:16 | - | - | - | Reserved 0 |

| 15:0 | dq_gc_start_msb_o | mr_dq_gc_start_msb_i | - | MSB of dq_gc, set to start save angles to alpha fifo |

slv_reg6 - R/W Access - Configuration & Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:3 | - | - | - | Reserved 0 |

| 2 | de_pair_delay_o | mr_de_pair_delay_i | - | define if fiber delay [gc] % dq_gc = 0 or 1, for 2nd AM |

| 1 | pair_delay_o | mr_pair_delay_i | - | define if fiber delay [gc] % dq_gc = 0 or 1, for PM |

| 0 | command_alpha _enable_o | mr_command_alpha _enable_i | Pull LOW to HIGH | Trigger to reset alpha fifo and save angles to fifo |

slv_reg7 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | command_gc _enable_o | mr_command_gc _enable_i | Pull LOW to HIGH | Trigger to reset gc_out fifo and save gc to fifo |

slv_reg8 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:0 | threshold_o | mr_threshold_i | - | number of clk200, define reading speed of gc_in fifo |

slv_reg9 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:0 | threshold_full_o | mr_threshold_full_i | - | unused(used to debug size of ddr4) |

slv_reg10 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:16 | de_fiber_delay_o | mr_de_fiber_delay_i | - | set alice_bob fiber delay [gc](only on Alice) found in calibration for 2nd AM, for reading angle out of DDR |

| 15:0 | fiber_delay_o | mr_fiber_delay_i | - | set bob/alice_bob fiber delay [gc] (on Bob/Alice) found in calibration for PM,for reading angle out of DDR |

slv_reg11 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:16 | - | - | - | Reserved 0 |

| 15:0 | ab_fiber_delay_o | mr_ab_fiber_delay_i | - | set alice_bob fiber delay [gc](only on Bob) found in calibration, to start output the gc+result |

slv_reg12 - R Access - Monitoring

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | pps_sync | pps_sync | - | monitor PPS so that Alice can capture to send START command |

slv_reg13 - R Access - Monitoring

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:9 | - | - | - | Reserved 0 |

| 8:7 | ddr_fifos_status_i | vfifo_idle | - | idle flags of axi virtual fifo |

| 6:5 | ddr_fifos_status_i | vfifo_full | - | full flags of axi virtual fifo |

| 4:3 | ddr_fifos_status_i | vfifo_empty | - | empty flags of axi virtual fifo |

| 2 | ddr_fifos_status_i | gc_out_fifo_full | - | full flag of gc_out fifo |

| 1 | ddr_fifos_status_i | gc_in_fifo_empty | - | empty flag of gc_in fifo |

| 0 | ddr_fifos_status_i | alpha_out_fifo_full | - | full flag of alpha_out fifo |

slv_reg14 - R Access - Monitoring

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:3 | - | - | - | Reserved 0 |

| 2 | fifos_status_i | gc_out_fifo_empty | - | empty flag of gc_out fifo |

| 1 | fifos_status_i | gc_in_fifo_full | - | full flag of gc_in fifo |

| 0 | fifos_status_i | alpha_out_fifo_empty | - | empty flag of alpha fifo |

slv_reg15 - R Access - Monitoring

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:0 | current_dq_gc_lsb_i | current_dq_gc_lsb_i | - | monitors the LSB of current dq |

slv_reg16 - R Access - Monitoring

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:16 | - | - | - | Reserved 0 |

| 15:0 | current_dq_gc_msb_i | current_dq_gc_msb_i | - | monitors the MSB of current dq |

Data flow

START

Alice sends START command to Bob through Ethernet. They both send the command to their FPGA, the START state will happen at next PPS and synchronise. Network latency has to be small enough, START command on Alice should not be close to the rising edge of PPS.

To make sure START command is not close to rising edge of PPS, Alice will request PPS detection from FPGA, she delays at least 10ms (PPS duty cycle) and send START command. Readback global counter on both Alice and Bob, compare to verify the synchronisation

WRITE MANAGEMENT

In START state, start to count up double global counter and write angles to DDR4. Angles are written as axistream data to AXI Virtual FIFO controller IP. This IP manages the memory map in the MIG, when you want to write or read from DDR4, you just need to manage write/read axistream of AXI Virtual FIFO controller.

The angle includes angle for PM and angle for the second AM. Dedicate 8bits to encode:

- 4 LSB : for PM angle

- next 2 bits : for 2nd AM angle

- 2 MSB : reserved zeros

GC PATH

Bob FPGA gets detection result, sends gc (dq_gc and q_pos) and click result to Bob OS, only output when gc higher than alice-bob fiber_delay. Bob then send gc to Alice (through Ethernet). They sends gc to their FPGA

READ DDR4 MANAGEMENT

When FPGA of each party receives gc, start reading angles from DDR4 based on values of gc and fiber delays value. Make sure fifo_gc_in is not full and AXI Virtual FIFO Controller is not full, by defining fifo_gc_in reading speed higher than click rate, define depth of Virtual FIFO large enough. Fiber delay from angle applied to Alice's 2nd AM is different with the one applied to Alice's PM, reading these angles respectively, then saving to the angles fifo with 4bits encoding:

- 2 LSB: for PM angle

- next 1 bit: for 2nd AM angle

- MSB: reserved zero

SAVE ANGLES

Start saving the angles read from DDR4 to fifo_alpha_out. Choose a moment(value of gc) to start saving, consider the fiber delay between parties. Each party have to read angles before fifo_alpha_out is full.

This is the picture describes the states in FPGA, the path of data between Alice and Bob.

Details in states COUNTING_*. Currently, Alice second AM is placed after Alice PM so the decoy_fiber_delay is shorter than ab_fiber_delay, we jump to COUNTING_AL first

Software control functions

- Ddr_Data_Reg : Set registers

- Ddr_Data_Init: reset ddr_data module

- Ddr_Status: monitoring the fifos flags, monitoring every 0.1s

Last test result List of commands

| step | Alice | Bob | expect |

|---|---|---|---|

| 1 | python -u server_ctl.py | ||

| python client_ctl.py init sp fg | histogram is good | ||

| 2 | python -u server_ctl.py | ||

| python client_ctl.py fd_b | 34 q_bins | ||

| 3 | python main.py bob --pol_ctl | ||

| 4 | python -u server_ctl.py | ||

| python client_ctl.py fd_a_mod | 15 q_bins | ||

| 5 | python -u server_ctl.py | ||

| python client_ctl.py fd_a | 4032 q_bins (10km fiber) | ||

| 6 | python main.py alice --ddr_data_reg 4 0 1999 0 0 | python main.py bob --ddr_data_reg 4 0 1999 0 0 | |

| python main.py alice --ddr_data_reg 3 0 1999 1992 0 | python main.py bob --ddr_data_reg 3 4000 1999 17 1 | ||

| python main.py alice --ddr_data_init | python main.py bob --ddr_data_init | ||

| python server_ddr.py | |||

| python client_ddr.py |

In step 6, there are some parameters:

- 1999: define speed of read gc_in fifo. This is for click rate more than 50k and less than 100k

- the delay and pair parameters defined from value of returned fiber delay after calibration

| calib fiber delay [q_bins] | pair_mode | fiber_delay |

|---|---|---|

| 34 | 1 | 17 |

| 35 | 0 | 18 |

| 36 | 1 | 18 |

| 37 | 0 | 19 |

- In server and client mechanism, try to START sending gc

- Reading alpha from alpha fifo when status of alpha_out_fifo is not empty. Pay attention to alpha out rate to avoid timeout on xdma

For testing single device, run ddr_loop_test.py. Detail is in Hardware Testing Chapter

TTL gate

Purpose of this module:

- Generate gate signal for SPD, level TTL 3.3V out of FPGA (level is converted on Bread70 for SPD)

- Duty cycle > 5ns

- Delay full range 12.5ns, fine delay in 100ps step

Port descriptions

| Signals name | Interface | Dir | Init status | Description |

|---|---|---|---|---|

| axil signals | s_axil | IO | - | standard axilite interface for r/w registers |

| s_axil_aclk | Clock | I | 15MHz | clock for axil interface |

| s_axil_aresetn | Reset | I | - | reset for axil interface, active LOW |

| clk240 | Clock | I | 240MHz | clock to generate gate signal |

| clk80 | Clock | I | 80MHz | clock for fine delay this gate signal |

| pps_i | - | I | - | PPS from WRS |

| ttl_rst | Reset | I | - | reset for logic, active HIGH |

| pulse_n/p | - | O | - | output to pins |

| pulse_rep_n/p | - | O | - | output to pins, without fine delay |

User parameters

| Parameter | Value | Description |

|---|---|---|

| C_S_Axil_Addr_Width | 8 | Address width of axil interface |

| C_S_Axil_Data_Width | 32 | Address width of axil interface |

| DELAY FORMAT | COUNT | Delay format for ODELAY3 |

| DELAY TYPE | VARIABLE | Delay type for ODELAY3 |

| DELAY VALUE | 50 | need to be between 45-65 taps for IDELAY3 calibrates correctly |

| REFCLK FRE | 300 | refclk for IDELAY3 and ODELAY3, default |

| UPDATE MODE | ASYNC | update by logic control |

Axil registers

- Base address: 0x0001_5000

- Offset address slv_reg(n) : 4*n

slv_reg0 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | ttl_trigger_enstep_o | en_step | pull 0-1-0.Stay HIGH long enough coresponding resolution | trigger fine delay master |

For example:

- Set fine delay tapes = 500 in software

- Resolution = 500*16 = 8000 (80MHz periods) = 0.1ms

- Trigger should stay HIGH longer than 0.1ms

This works the same for slave 1 and slave 2 cascaded to master

slv_reg1 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:23 | - | - | Reserved 0 | |

| 22:19 | ttl_params_o | duty_val | Set duty cycle width, 1 step is 1 period of 240MHz | |

| 18:15 | ttl_params_o | delay_val | Set tune step, 1 step is 1 period of 240MHz | |

| 14:1 | ttl_params_o | resolution | max is 8192 | Set length of fine delay step on master ODELAY3 |

| 0 | ttl_params_o | increase_en | 1: increase 0: decrease | Set fine delay direction on master ODELAY3 |

The resolution is in unit of [80MHz period]

- Maximum fine delay tap: 512

- Require 16 clk cycles for each tap

- Resolution = 512*16 = 8192

slv_reg2 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | ttl_params_en_o | ttl_params_en_o | pull 0-1 | Enable register update |

slv_reg3 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31 | - | - | Reserved 0 | |

| 30:17 | ttl_params_slv_o | resolution_slv2 | max is 8192 | Set length of fine delay step on slave 2 ODELAY3 |

| 16 | ttl_params_slv_o | increase_en_slv2 | 1: increase 0: decrease | Set fine delay direction on slave 2 ODELAY3 |

| 14:1 | ttl_params_slv_o | resolution_slv1 | max is 8192 | Set length of fine delay step on slave 1 ODELAY3 |

| 0 | ttl_params_slv_o | increase_en_slv1 | 1: increase 0: decrease | Set fine delay direction on slave 1 ODELAY3 |

slv_reg4 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | ttl_trigger_enstep_slv1_o | en_step_slv1 | pull 0-1-0.Stay HIGH long enough coresponding resolution | trigger fine delay slave 1 |

slv_reg5 - R/W Access - Trigger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | ttl_trigger_enstep_slv2_o | en_step_slv2 | pull 0-1-0.Stay HIGH long enough coresponding resolution | trigger fine delay slave 2 |

Software control

Generate signal

- Clock domain: 240 MHz

- Trigger PPS and align the pulse to PPS

- Change duty and tune delay the pulse with duty_val and delay_val

- Output will be fed into fine delay

These are the base functions allow to set registers, generate signal, change duty cycle and tune delay

Fine delay

AMD support ODELAYE3 primitives to delay a signal in ps step, full range is 1,25ns. Read UG974 and UG571 for more details

Tune delay step is around 4,16ns. So, I choose Cascade configuration for ODELAYE3

- DELAY_FORMAT = COUNT

- DELAY_TYPE = VARIABLE

- UPDATE_MODE = ASYNC

Trigger the fine delay on master and 2 slaves, every trigger will shift your signal fine [taps] set in write_delay_* function

Decoy signal

Purpose of this module:

- Generate signal for the second AM

- Level is 0 or 1, apply randomly on qbit(12,5ns)

- Source of RNG is from second tRNG SwiftPro RNG

decoy_rng_fifos.v

Port descriptions

| Signals name | Interface | Dir | Init status | Description |

|---|---|---|---|---|

| s_axis_tdata[127:0] | s_axis | I | - | tRNG data come from xdma_h2c stream |

| s_axis_tvalid | s_axis | I | - | data valid indication from xdma_h2c stream |

| s_axis_tready | s_axis | O | - | ready signal from logic |

| s_axis_clk | Clock | I | 250MHz | Clock of axistream |

| s_axis_tresetn | Reset | I | - | Reset of axistream, active LOW |

| clk200 | Clock | I | 200MHz | Clock for logic |

| tx_core_rst | Reset | I | - | Using same reset with rng fifos in fastdac |

| rd_en_16 | - | I | - | Enable signal at 10MHz, in clk200 domain |

| rd_en_4 | - | I | - | Enable signal at 40MHz, in clk200 domain |

| de_rng_dout[3:0] | - | O | - | tRNG output at 40MHz |

decoy.v

Port descriptions

| Signals name | Interface | Dir | Init status | Description |

|---|---|---|---|---|

| s_axil signals | s_axil | IO | - | standard s_axil interface |

| s_axil_aclk | Clock | I | 15MHz | clock for axil interface |

| s_axil_aresetn | Reset | I | - | reset for axil interface, active LOW |

| clk240 | Clock | I | 240MHz | clock to generate gate signal |

| clk80 | Clock | I | 80MHz | clock for fine delay this gate signal |

| clk200 | Clock | I | 200MHz | clock to generate gate signal |

| pps_i | - | I | - | PPS from WRS |

| decoy_rst | Reset | I | - | reset for logic, active HIGH |

| rd_en_4 | - | I | - | Enable signal at 40MHz, in clk200 domain |

| rng_value[3:0] | - | I | - | tRNG input at 40MHz |

| decoy_signal_n/p | - | O | - | decoy signal output to pins |

| decoy_signal | - | O | - | decoy signal output without delay |

| the others signals | - | O | - | for debug on ILA |

User Parameters

| Parameter | Value | Description |

|---|---|---|

| C_S_Axil_Addr_Width | 12 | Address width of axil interface |

| C_S_Axil_Data_Width | 32 | Address width of axil interface |

| DELAY FORMAT | COUNT | Delay format for ODELAY3 |

| DELAY TYPE | VARIABLE | Delay type for ODELAY3 |

| DELAY VALUE | 50 | need to be between 45-65 taps for IDELAY3 calibrates correctly |

| REFCLK FRE | 300 | refclk for IDELAY3 and ODELAY3, default |

| UPDATE MODE | ASYNC | update by logic control |

Axil registers

- Base address: 0x0001_6000

- Offset address slv_reg(n) : 4*n

slv_reg0 - R/W Access - Triiger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | reg_enable_o | reg_enable_o | pull 0-1 | Enable register update |

slv_reg1 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:4 | - | - | - | Reserved 0 |

| 3:0 | tune_step_o | tune_step_o | 8 steps max in logic | Set tune step for decoy signal, 1 step is 1 period of 240MHz |

slv_reg2 - R/W Access - Triiger Control

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:3 | - | - | - | Reserved 0 |

| 2 | trigger_enstep_slv2_o | trigger_enstep_slv2_o | pull 0-1-0.Stay HIGH long enough coresponding resolution | trigger fine delay slave 2 |

| 1 | trigger_enstep_slv1_o | trigger_enstep_slv1_o | same as slave 2 | trigger fine delay slave 1 |

| 0 | trigger_enstep_o | trigger_enstep_o | same as slave 2 | trigger fine delay master |

slv_reg3 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:1 | - | - | - | Reserved 0 |

| 0 | decoy_rng_mode_o | decoy_rng_mode_o | 0: from dpram 1: from tRNG | Choose rng source |

slv_reg5 - R/W Access - Configuration

| Bits | Signal name | HW Wire | Action/Value | Description |

|---|---|---|---|---|

| 31:15 | - | - | Reserved 0 | |